8 Sep 2025

In modern workplaces—from manufacturing plants to office cubicles—ergonomics is essential to creating environments that promote safety, health, and efficiency. Defined by OSHA as “the science of designing the job to fit the worker,” ergonomics focuses on aligning job tasks, equipment, and workspaces with human capabilities and limitations (OSHA, Ergonomics Overview).

Incorporating ergonomics into workplace safety programs is a proven method to reduce musculoskeletal disorders (MSDs), improve employee well-being, and cut down on costly injuries. Employers who take ergonomics seriously don't just comply with OSHA—they build safer, more productive operations.

The Ergonomic Injury Epidemic: Why It Matters

MSDs account for one-third of all worker injury and illness cases.

Many of these injuries stem from:

- Repetitive tasks

- Forceful exertions

- Awkward postures

- Prolonged static positions

These hazards are often preventable. That’s where ergonomics steps in—tailoring tasks to human needs instead of forcing the human body to adapt unnaturally to poorly designed work environments.

While OSHA does not have a specific ergonomics standard, it enforces the General Duty Clause (29 U.S.C. § 654, 5(a)(1)), which requires employers to provide a workplace free from recognized serious hazards—including ergonomic ones.

OSHA’s Recommended Ergonomics Practices

OSHA offers a framework for developing effective ergonomics programs. These are part of its broader Recommended Practices for Safety and Health Programs (OSHA Safety and Health Programs) and are based on successful implementation in high-risk industries such as healthcare, warehousing, and manufacturing.

1. Management Commitment & Worker Involvement

A successful ergonomics program starts with leadership support and worker input. OSHA recommends involving employees in identifying hazards and crafting solutions, ensuring the changes make sense in real work settings.

2. Worksite Analysis

Employers should analyze tasks to identify ergonomic risk factors. This involves:

- Reviewing OSHA 300 logs and injury reports

- Observing work practices

- Conducting job hazard analyses (JHA) per 29 CFR 1910.132(d) (hazard assessment for PPE)

- Surveying employees for pain points

By identifying high-risk tasks, employers can prioritize areas for intervention.

3. Hazard Prevention and Control

Once risks are identified, employers must eliminate or control them using a hierarchy of controls:

- Engineering Controls: Most effective. Examples include adjustable desks, anti-fatigue mats, or mechanical lifting aids.

- Administrative Controls: Job rotation, micro-break schedules, and reducing shift lengths.

- Work Practice Controls: Training workers on safe body mechanics and proper tool use.

Although not mandated by a specific OSHA standard, implementing controls aligns with OSHA’s general duty expectations and PPE requirements under 29 CFR 1910 Subpart I.

4. Education and Training

Training should empower workers to:

- Recognize ergonomic risk factors

- Use tools and equipment properly

- Maintain neutral postures

- Report early symptoms of MSDs

Supervisors should also be trained to recognize signs of strain and know how to respond. OSHA emphasizes the importance of job-specific training under 29 CFR 1910.1200(h) (Hazard Communication) and supports ergonomic awareness for injury prevention.

5. Program Evaluation and Improvement

Ergonomic programs require ongoing assessment. OSHA encourages employers to:

- Track MSD rates

- Solicit employee feedback

- Reassess job tasks after modifications

- Monitor the effectiveness of implemented controls

Employers can use metrics such as injury rates, productivity levels, or absenteeism trends to gauge program success.

Common Ergonomic Hazards and Solutions

Here’s a breakdown of typical ergonomic issues and OSHA-recommended solutions:

| Risk Factor | Hazard Example | Ergonomic Solution |

| Repetitive Motion | Assembly lines, typing | Task variation, automation, adjustable tools |

| Awkward Posture | Overhead reaching, bending, twisting | Repositioning work materials, better workstation design |

| Forceful Exertions | Lifting, pushing, or pulling heavy items | Mechanical lifts, team lifts, carts |

| Static Posture | Sitting/standing too long | Sit-stand desks, anti-fatigue mats, micro-breaks |

| Contact Stress | Pressing against hard surfaces or tools | Padding, tool redesign |

Remote Work and Ergonomics

With the rise of remote and hybrid work, home office ergonomics is just as important. OSHA suggests:

- Chair: Supportive with lumbar support and adjustable height

- Monitor: Positioned at eye level, 20-30 inches from face

- Keyboard/Mouse: Aligned to prevent wrist strain

- Breaks: Frequent stretching or movement every 30–60 minutes

Though OSHA may not inspect home offices, it still holds employers accountable for ensuring workers have safe work conditions—even remotely.

Build Healthier Jobs from the Inside Out

When employers proactively tackle ergonomic hazards, the benefits go far beyond injury prevention. A well-executed ergonomics program leads to:

- Lower workers' compensation costs

- Reduced absenteeism

- Higher morale and job satisfaction

- Increased productivity

- Better employee retention

OSHA may not have a standalone ergonomics rule, but the tools and guidance it offers empower employers to address these risks effectively. By aligning with 29 U.S.C. § 654 (General Duty Clause) and OSHA’s Recommended Practices, businesses create safer, more sustainable work environments.

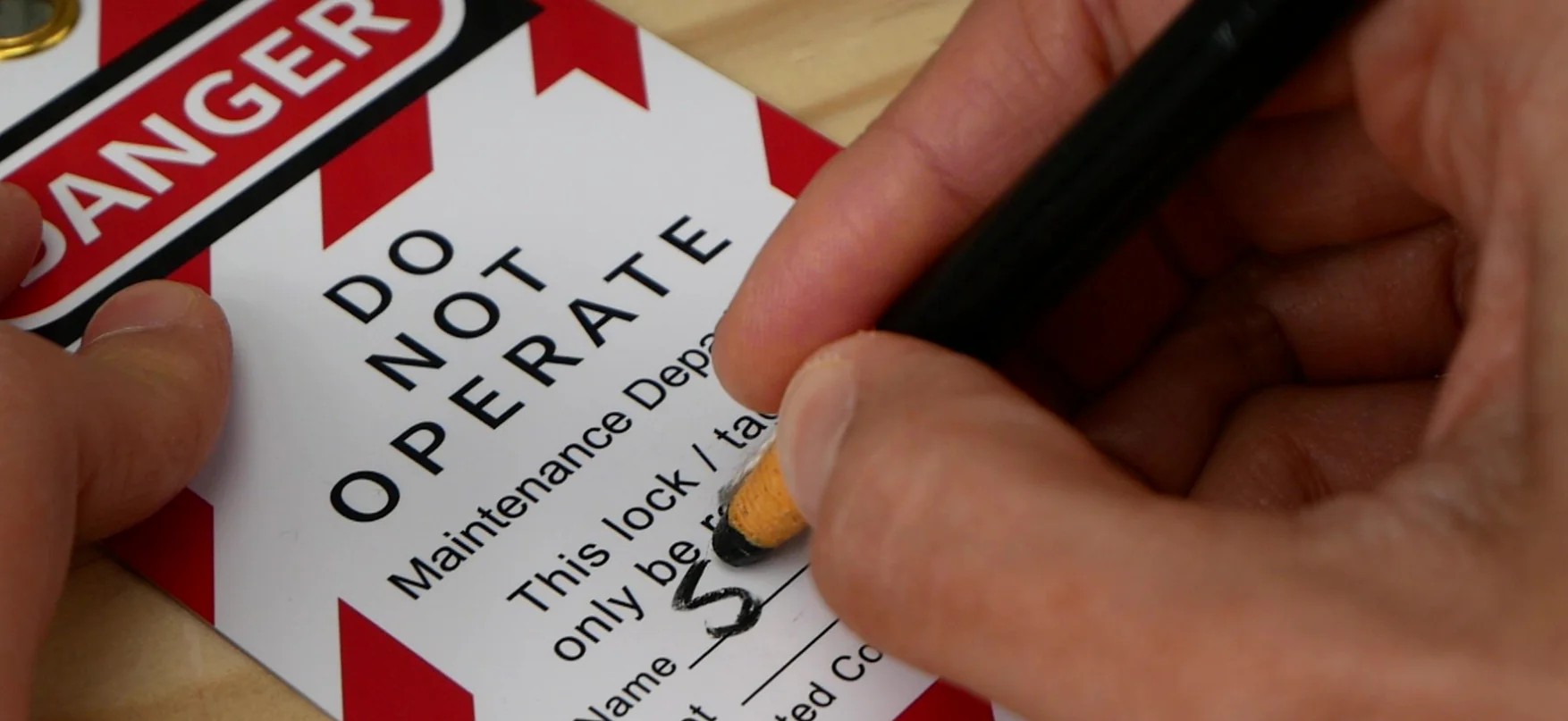

Enhancing Ergonomics with an EHS Management System

Modern ergonomics programs are most effective when integrated into a comprehensive Environmental, Health, and Safety (EHS) management system. Tools like OSHEPRO’s ORBIT® (Observation Reporting and Behavior Improvement Tool) help organizations improve behavior-based safety by capturing near-misses, unsafe acts, and ergonomic observations, fostering proactive risk reduction. For task-specific risks, TRACI® (Task Risk Assessment Control & Implementation) enables detailed machine risk assessments, job hazard analyses (JHA), and Lockout/Tagout (LOTO) procedure management, ensuring that high-risk ergonomic tasks are systematically controlled. Additionally, AMLA® (Accident Management & Loss Analysis) provides a centralized platform to track employee injuries, maintain OSHA 300 Logs, and log environmental or property incidents. By leveraging these tools, employers can identify ergonomic hazards faster, implement corrective actions more efficiently, and monitor trends over time—strengthening both safety culture and compliance while reducing musculoskeletal disorders, incidents, and operational losses.

.png)

.png)

.png)

.jpg)