27 Jun 2025

On June 26, 2025, OSHA announced a renewed National Emphasis Program on Amputations in Manufacturing Industries, extending its focus for the next five years. The initiative reflects a dedicated effort to identify and reduce amputation risks linked to operating, servicing, or maintaining industrial machinery—an industry-wide wake-up call for manufacturers.

What OSHA’s Renewed Emphasis Program Targets

Under this NEP:

- OSHA inspectors will systematically evaluate compliance with machine guarding standards and hazardous energy control (better know as Lockout‑Tagout or LOTO) procedures during operation, servicing, and maintenance tasks

- The program expands to include additional high-risk industries based on NAICS codes.

- Facilities previously inspected under the NEP in the past 24 months with no reported amputations may be removed from the current inspection list

It’s clear OSHA views two key issues as instrumental to reducing amputations: ensuring proper machine guarding and enforcing rigorous energy isolation protocols.

1. Machine Guarding: Your First Line of Defense

Machine guards are physical or electronic barriers designed to prevent workers’ hands or limbs from reaching dangerous points—nip, pinch, shear, or cut points. OSHA requires:

- Fixed, interlocked, or adjustable guards to cover hazardous moving parts.

- Presence-sensing devices or light curtains on newer machinery.

- Regular inspections to ensure guards remain intact, secure, and properly adjusted.

Failing to maintain effective guarding can result in severe injuries—and costly OSHA citations, especially under heightened scrutiny from the NEP.

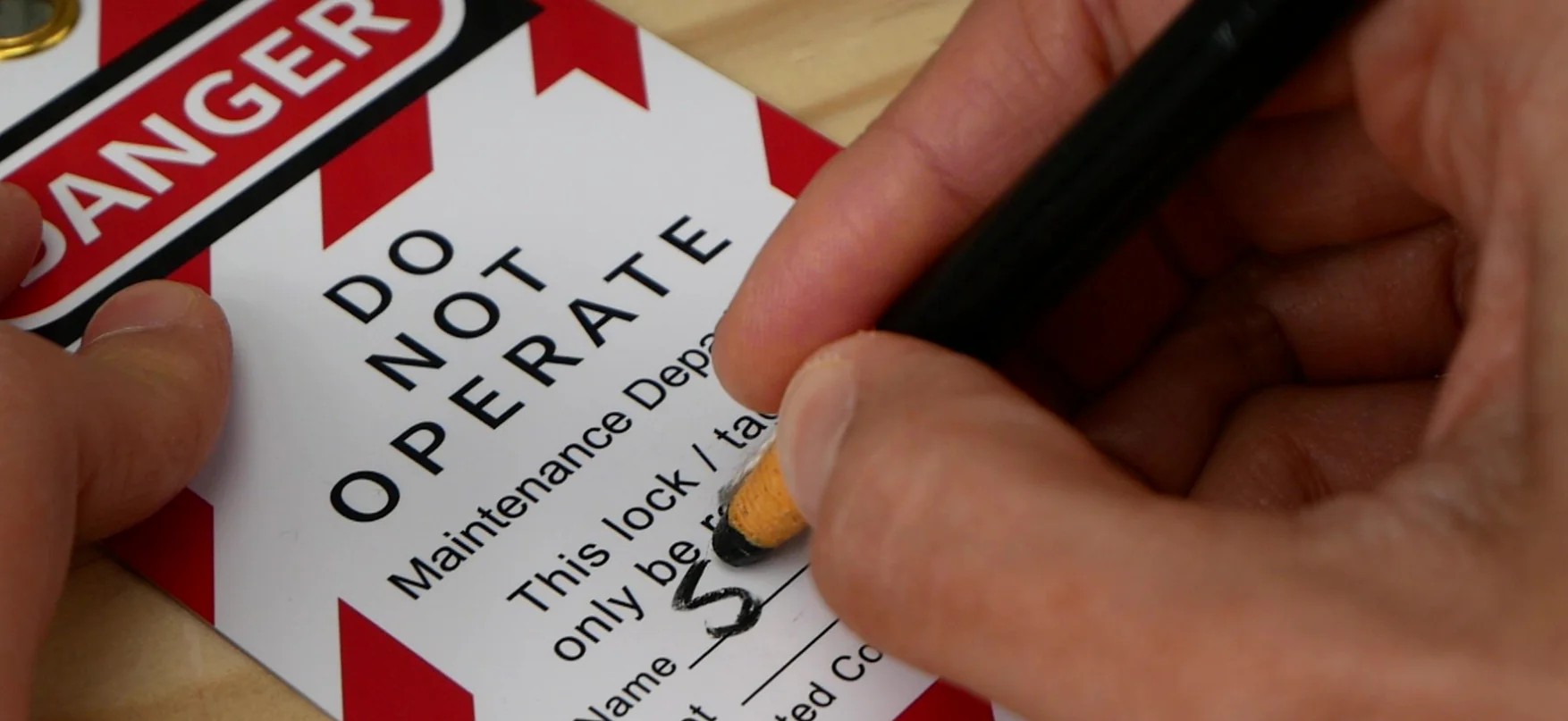

2. Lockout‑Tagout (LOTO): Controlling Hazardous Energy

LOTO procedures are the only way to guarantee machinery cannot unexpectedly start while maintenance is in progress. Best practices include:

- Issuing lockout devices and standardized tags.

- Providing specialized employee training.

- Conducting periodic audits & inspections of energy control procedures.

- Ensuring authorized personnel are conducting lockout steps—and verifying energy isolation.

Under the NEP, noncompliance with LOTO increases risk exposure—and the likelihood of inspection outcomes leading to penalties.

How OSHEPRO and TRACI® Simplify Compliance and Cut Risk

To avoid the high cost of OSHA violations, businesses need robust, practical systems for machine safety. OSHEPRO’s TRACI® (Task Risk Assessment, Control & Implementation) offers an all-in-one, in‑house solution to simplify compliance and build confident safety programs.

1. Comprehensive Machine Guarding Assessments

TRACI® provides:

- Guided walkthrough checklists tailored to specific machine types (e.g., presses, saws, conveyors).

- Risk‑level scoring—pinpoint where guarding is inadequate, missing, or improperly adjusted.

- Automatic recommendations for guard upgrades (e.g., interlocked covers, perimeter fencing, light curtains).

- Documentation of corrective actions with timeframes, ownership, and completion status.

By standardizing machine hazard reviews, TRACI® empowers safety teams to proactively fix weaknesses before OSHA inspectors are involved.

2. Full‑Spectrum LOTO Plans & Programs

TRACI® streamlines energy control programs:

- Automatically generate LOTO procedures for all equipment with stored energy.

- Attach relevant equipment diagrams and energy flow charts.

- Schedule annual refresher training for authorized workers.

- Include audit checklists to track compliance, deviations, and corrective measures.

This organized, evidence‑based approach means businesses demonstrate they’re fully aligned with OSHA’s requirements.

Why This Matters

With OSHA now publishing a sharper focus on machining-related amputations, companies must ensure their machine guarding and energy control systems are not just documented—but live, tracked, and continually improved. TRACI® helps companies:

- Avoid fines and costly incident investigations tied to amputations or lost‑time accidents.

- Boost worker confidence, knowing their safety protocols are reliable.

Shorten inspection times, showing inspectors complete records, checklists, and repair logs on demand.

Act Proactively: Leverage Digital Tools for NEP Compliance

OSHA’s renewed NEP is a clear message: manufacturing safety isn’t optional. As machine guarding and LOTO controls come under the microscope, organizations can no longer rely on reactive approaches—they need full‑cycle, digital tools to manage compliance.

OSHEPRO’s TRACI® is designed precisely for this purpose: to guide teams through detailed assessments, track every corrective action, and maintain rigorous energy isolation programs. It offers the documentation and transparency necessary to not only pass OSHA inspections— but to truly protect employees and preserve operations.

For manufacturers striving to stay compliant under the new NEP and create safer workplaces, adopting a proactive, software-driven approach isn’t just smart—it’s essential.

.png)

.png)

.png)

.jpg)